How to Build a Mobile Cattle Water System

For Your Pasture Rotation

Image Credit: Bryan Ledgard, Flickr, CC BY 2.0

In this article I will show you how to build a mobile cattle water system for your rotational grazing program.

This simple and easy to build livestock water system will ensure that you can get water to every single grazing slice in your pasture rotation, even when using daily pasture moves and portable electric fences to create flexible pasture sizes that change throughout the grazing seasons.

Flexible pasture slices require a cattle water system that is also flexible, as I discussed in Part III of the Smart Electric Fence Grid - how to integrate your livestock watering system into your electric fence grid. A mobile water trough that connects to a network of polyethylene pipes provides this flexibility at a very low cost. It is the perfect cattle water system to fit with a daily rotational grazing program.

This article will give you an overview of how to build your own mobile cattle water system, including where and how to lay out your grid of polyethylene water lines, how to connect your water tub to your water lines, how to ensure that the trough is easy to move during daily pasture moves, what kind of trough valve to install inside your cattle water tub, and how to keep your above-ground waterlines and connection hose safe from trampling.

Once you are ready to actually begin building your mobile livestock water system, you will find handy reference tables for calculating the correct pipe dimensions and water pressure requirements in my book, Grass-Fed Cattle: how to produce and market natural beef. These reference tables will ensure that your waterlines will be sized correctly to comfortably meet all your herd's daily cattle water requirements and peak demand flow rates, even in the furthest corners of your pasture rotation.

Water System Overview

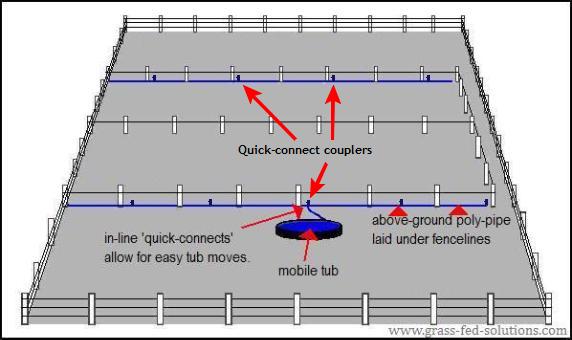

The image below shows the basic overview of the water pipe network and mobile cattle water system. I'll explain each component individually below:

|

This mobile cattle water system used polyethylene pipes laid above-ground, directly underneath every second permanent electric fence line. Quick-connect couplers in the water lines allow you to easily attach a flexible hose that will supply your mobile water trough from the the PE pipe grid. |

The Water Lines

The water lines that supply your mobile water system are best constructed using cheap flexible polyethylene pipe (PE pipe). PE pipe comes in large rolls in a wide range of pipe diameters, water pressure ratings and pipe lengths. It is easily cut with a utility knife or tin snips and its flexibility ensures that you can wind it around corners without having to make joints.

The fastest and easiest way to install it is to simply lay it above-ground directly underneath the permanent electric fences that you build to create your main permanent electric fence corridors. You only need to lay your pipe grid under every second permanent fence line since it can be accessed from either side of the fence by the mobile cattle water tub. By laying it underneath the permanent electric fence corridors you ensure that the pipe is protected against trampling.

A handy tip for installing it is to build a simple A-frame with a removable center pipe to hold your rolls of polyethylene pipe - a larger version of this home-made wire un-roller is shown on page 209 of my book Grass-Fed Cattle. I like to strap the pipe un-roller into my ATV trailer (page 100 of Grass-Fed Cattle) so I can tie one end of the pipe onto a post and then drive while the pipe un-rolls behind me.

Overcoming solar expansion and solar heating in your pipes:

Reminder

If your cattle herd starts to bunch up around the water trough in distress, without touching their water, check the water temperature in the trough. You may need to flush a line - solar heating may be the culprit.

Polyethylene pipe contracts or expands considerably during temperature changes, so always install it early in the morning during cool weather to ensure that your joints and measurements will still line up on cold days when the pipe contracts.

In hot climates you may need to cover the polyethylene pipe with either plant debris, sawdust, or a thin layer of dirt to shade the pipe in order to prevent sunshine heating the water inside these black polyethylene pipes. The grass residue that naturally builds up within a year or two after the pipe is laid out is often enough. (When I initially laid out my water lines, I used a weed trimmer along the pipe lines to knock down some of the tall grass to create a thin shade cover for the pipes - once the grass rots down the cattle won't eat it so you won't likely need to repeat it.)

Burying pipe

Alternately, you may want to bury the pipe just below the soil surface. A curved pipe welded to the side of a sub-soiler shank works well for installing polyethylene pipe below ground. This setup is shown on page 101 of Grass-Fed Cattle. This setup allows you to feed pipe down the side of the ripper shank without having to dig open trenches through your pastures. If you install pipe below-ground, it is doubly important to ensure that you install pipe during cool weather and early in the morning so that pipe contraction during cool weather does not pull apart your joints underground.

Junctions

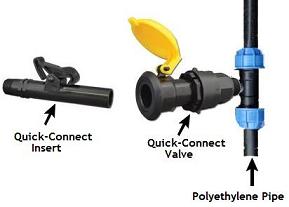

It is important to install ball valves, like the ball valve shown on the right, at main junctions in your pipe network so you can repair individual sections of pipe without shutting off your entire livestock water supply. It also helps to minimize flooding in fields if you have to drain individual sections for repairs.

These ball valves are also crucial for blowing out individual sections of water lines to winterize your pipe grid before the frost season, which I'll discuss further below.

Calculating Pipe Diameter and Flow Rates

The pipe diameter you choose will depend of the daily livestock water requirements and peak flow rates required at your trough. Always calculate pipe diameter based on the furthest distance you need to pump water because water pressure and flow rates decline due to friction inside your pipes. The narrower the pipe diameter, the higher the friction losses.

You can reduce pressure losses caused by friction by constructing mainlines with larger diameter pipe and then step down the pipe diameter to construct the shorter side-branches of your livestock water supply network. You also need to account for gravity-induced pressure gains or losses so that your water pressure and flow rates are appropriate throughout your entire water supply network.

Polyethylene pipe is typically designed to handle household water pressure. Some brands are rated for even higher pressure, but keep in mind that increasing pressure to increase flow rates will also increase your pumping costs - it is often cheaper to increase pipe diameter slightly to reduce friction losses in order to maintain your required flow rates at the trough. It is also usually cheaper to install pressure reducing valves, like the pressure reducer valve shown on the right, to overcome high pressure gains caused by gravity (pumping downhill) so you can stick to the much cheaper PE pipe that is only rated for typical household pressures.

The "Grazing Infrastructure" chapter of my book, Grass-Fed Cattle, provides detailed step-by-step calculations for calculating flow rates and water pressures for your cattle water system, including how to account for pressure gains or losses caused by gravity. The handy quick-reference tables provided in this chapter will help you calculate the pressure losses and changes in flow rates caused by friction inside your pipes for a wide range of pipe diameters for both polyethylene and PVC pipes. When you are ready to begin designing your water system, you will find all the calculations and formulas you need in this chapter - you can simply plug in your own numbers into the sample calculations.

Frost-proofing your water lines

If you live in a frost-prone area, ensure that you can access your water pipe network with an air compressor. By using the ball valves, you can isolate individual sections of pipe, which allows you to blow the majority of the water out of your lines.

Each branch of your PE pipe network should end with a quick-connect coupler or a removable plug, so that you can drain and blow out the lines with your air compressor.

The Water Trough

When it comes to the cattle water tub that you will use as your mobile water trough, bigger is better. A large tub accomplishes several things:

- A large-capacity tub ensures that there is a large volume of water immediately available for drinking, which helps significantly reduce your peak flow rate requirements at the trough.

- A large-capacity tub also ensures that your cattle herd does not perceive water to be a limited resource because a large number of cattle can drink simultaneously without having to wait for the trough to refill. Perceptions are everything to cow psychology. By preventing wait times, the cattle do not perceive the water to be a limited resource so they will relax and drift in to the trough individually to drink whenever they feel like it. This spreads pressure on the trough throughout the day rather than having the cattle all mob the trough at once, which causes unnecessary trampling and damage to the pasture soil around your cattle water trough.

- A large-capacity tub is also less likely to get completely drained while the cattle drink - you need the weight of the water to ensure that the tub does not get pushed all over the pasture.

While tub size obviously should obviously be matched to the size of the cattle herd, I like tubs with at least a 300 gallon capacity - more for larger herds. The tub should also be round, which makes it harder to knock over and maximizes the number of cattle that can drink at once.

Some livestock water tubs come with two drain plugs pre-installed. You will need one of these threaded drain holes to plumb in the trough valve, which I'll discuss separately further down on this webpage. The second is for draining the tub between pasture moves.

If your tub does not come with a second threaded port, you will need to install your own by cutting a hole in the sidewall. Most hardware stores will have something to get the job done, or you can order a kit from various tub suppliers - Rubbermaid carries special tank drain plug kits for around $20.00. Gallagher Animal Management Systems also makes 1" and 1.25" diameter bulkhead fittings specifically for this purpose.

While a threaded cap or drain plug will work, it is best to use a

tapered heavy-duty rubber plug to plug the hole from inside the tub so

you can remove the plug quickly - after all, to keep up with your

pasture rotation you will need to drain and move the tub every day (or

every other day - you can use the same site twice by making a slight

alteration to your portable cross fence between pasture moves).

Pull

the plug just before starting the pasture move so the tub will be

drained by the time your cattle have been moved to the next pasture. You

don't want your cattle to find an empty trough!

Even a half hour without water in the fresh pasture slice will completely alter your cattle's behaviour. The first individuals will begin drifting in for a drink about a half hour or so following a pasture move. If they find the tub empty, you will quickly find the entire herd mobbing the empty water tub. If this happens, the tub won't have a chance to fill prior to the herd starting to drink, so it won't be heavy enough to prevent the cattle herd from pushing it all over the pasture, potentially breaking the connecting hose that connects the trough to the water line.

At 10 gallons per minute, a 300 gallon tub will take a half hour to fill - that's roughly the time window before the first cattle start drifting to the livestock water trough after a pasture move. If the first cattle arrive for water before your tub has been drained, moved, and at least partially refilled, then the cattle will mob the trough and suck the water back out of the trough faster than it can refill. And you'll be there for most of the morning waiting for the tub to get heavy enough to prevent the cattle from pushing it all over your pasture. Timing is everything.

Quick Connect Couplers & Hoses

To connect the cattle water tub to the polyethylene pipe grid, install quick-connect couplers in the polyethylene pipes at regular intervals. These quick couplers make it extremely easy to move and re-connect your water trough to the polyethylene pipe grid.

To supply the trough, the quick coupler insert should be attached to a flexible, collapsible 1"-2" diameter hose made of fire-hose material. Most irrigation-supply stores sell these hoses as they are also used to attach moveable irrigation reels to the shut-off valves on top of the water mains. These hoses are designed to be extremely robust and flexible, and they can be stepped on by cattle without breaking. This hose should be at least 40 ft long so you have some flexibility about where you place your water trough although the trough itself should be placed against the electric fence so the side where the hose enters the tank is protected from cattle.

The other end of the fire hose should attach to the water tub through one of the two drain ports (bulkhead fittings) discussed earlier.

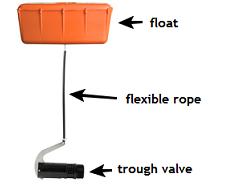

Stock-Proof Water Trough Valve

Use a stock-proof trough valve (like the stock-proof trough valve from Gallagher Animal Management Systems shown on the right) inside the water tub to control the flow of water into the tank.

This trough valve design places the valve at the very bottom of the trough rather than at the trough rim to keep it safe from damage from the cattle. The float is attached to the valve using string rather than a solid float arm like those inside your toilet tank so that the cattle can nose at the float while drinking without breaking the valve.

That's it - that completes the mobile cattle water system for your rotational grazing program!

Happy grazing!

Thumbbnail Image Credit: Bryan Ledgard, Flickr, CC BY 2.0

Related Articles:

(Disclosure: I get commissions for purchases made using Amazon links in my post.) And when you're ready to start planning your cattle farm, check out my book: Grass-Fed Cattle: How to Produce and Market Natural Beef. Use the links below to explore my book and read reviews on Amazon:

|